Introducing the Direct Materials Quantity Variance Calculator, an indispensable tool that empowers businesses to pinpoint inefficiencies, optimize production processes, and maximize profitability. Delve into the intricacies of this variance, its causes, and its transformative role in decision-making.

The Direct Materials Quantity Variance Calculator provides a comprehensive understanding of the variance between the actual and standard quantities of direct materials used in production, enabling businesses to identify areas for improvement and make informed decisions.

Direct Materials Quantity Variance

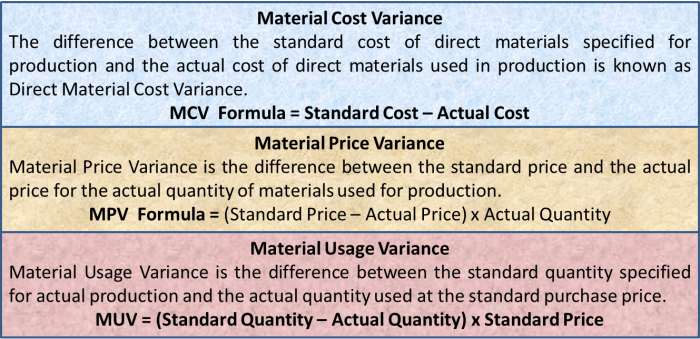

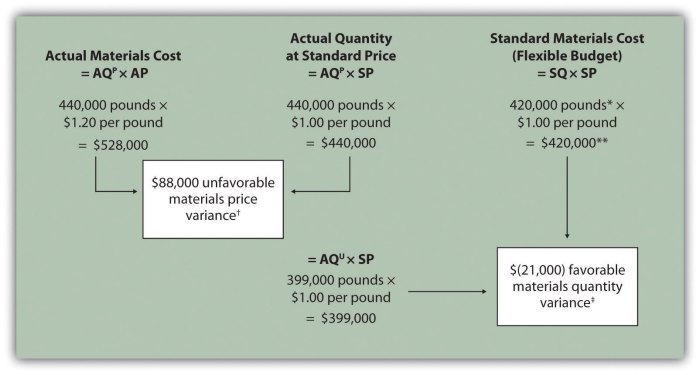

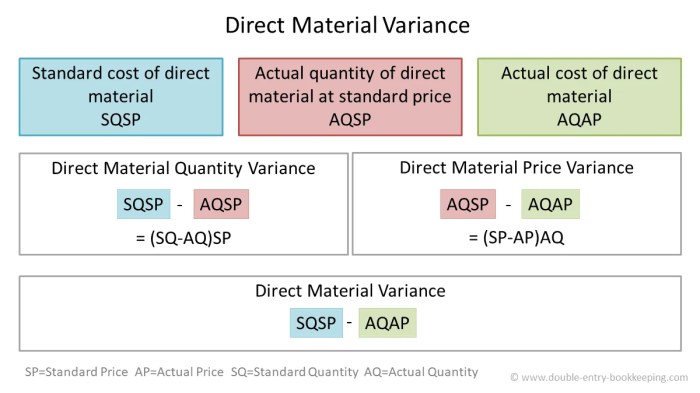

Direct materials quantity variance measures the difference between the actual quantity of direct materials used in production and the standard quantity that should have been used, based on the standard cost of production.

The formula for calculating direct materials quantity variance is:

DMQV = (Actual Quantity

Standard Quantity) x Standard Price

For example, if the actual quantity of direct materials used in production is 10,000 units, the standard quantity is 9,500 units, and the standard price is $10 per unit, then the direct materials quantity variance would be:

DMQV = (10,000

9,500) x $10 = $500 unfavorable

Causes of Direct Materials Quantity Variance

There are many common causes of direct materials quantity variance, including:

- Material usage inefficiencies

- Scrap and waste

- Incorrect material specifications

- Supplier errors

- Production inefficiencies

Each of these causes can have a significant impact on the variance, and it is important to identify and address the root cause in order to improve production efficiency.

Using Direct Materials Quantity Variance for Decision Making, Direct materials quantity variance calculator

Direct materials quantity variance can be used to improve production efficiency by identifying areas where materials are being used inefficiently.

For example, a company may find that it is experiencing a large unfavorable direct materials quantity variance due to material usage inefficiencies.

The company can then investigate the cause of the inefficiencies and take steps to correct them, such as:

- Improving employee training

- Investing in new equipment

- Implementing a quality control program

Advanced Topics in Direct Materials Quantity Variance Analysis

There are a number of more advanced topics in direct materials quantity variance analysis, including:

- Using statistical techniques to analyze variance

- Developing variance budgets

- Implementing variance control systems

These topics can be used to further improve the accuracy and effectiveness of direct materials quantity variance analysis.

FAQ Section: Direct Materials Quantity Variance Calculator

What is the formula for calculating direct materials quantity variance?

Direct Materials Quantity Variance = (Standard Quantity – Actual Quantity) x Standard Price

How can direct materials quantity variance be used to improve production efficiency?

By identifying the causes of the variance, businesses can implement corrective actions to reduce waste, optimize processes, and improve overall efficiency.

What are the limitations of using direct materials quantity variance for decision-making?

While valuable, direct materials quantity variance should be used in conjunction with other metrics to provide a comprehensive view of production performance.